| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : EN

Model Number : 22000

Certification : API, AISI, ISO

Place of Origin : China

MOQ : 1 Pcs

Price : USD 2000-20000 Unit

Payment Terms : L/C, T/T

Supply Ability : 5000 PCS / Year

Delivery Time : 2-4 Weeks

Packaging Details : Wooden Box

Type : Diamond Drill Bit

Use : Coal Mining / Pcd Impregnated Diamond Exploration PDC Bits

Material : Stainless Steel,diamond,Polycrystalline diamond compact

Processing type : Forging,Casting,sintering item

Application : Rock Drilling , oil ,mining ,gas .water

Product name : large size drilling tool

Shipment : according to requirement

Rock PDC Bit 22 inch 6 Blades PDC Diamond Bit of Oilfield Drill Bit

Description:

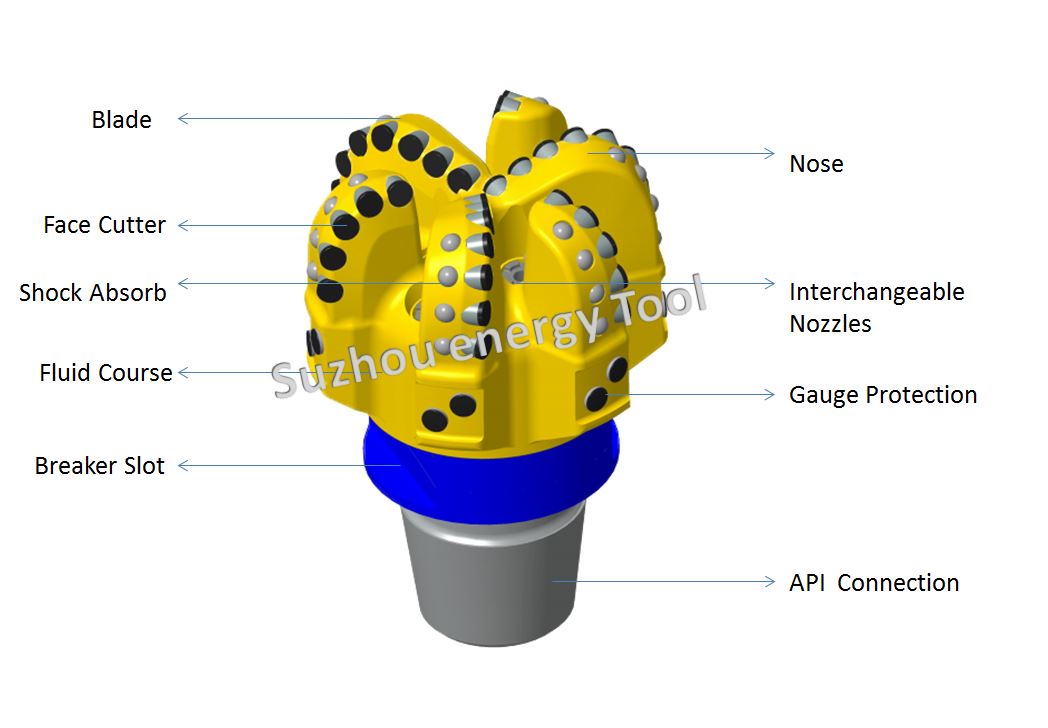

PDC drill bits are efficient tools used for rock drilling. With a compact external structure typically composed of multiple polycrystalline diamond compact (PDC) cutters, they exhibit high hardness and wear resistance. Widely employed in areas like oil drilling and geological exploration, PDC drill bits enable rapid and precise drilling through various geological formations. Renowned for their excellent performance, they boast high efficiency, strong stability, and long service life, excelling in complex geological conditions. PDC drill bits are indispensable tools in modern drilling applications

All our drill bits conform to the API standard and are utilized in the drilling industry. We offer PDC drill bits ranging in size from 3 to 22 inches, equipped with 3 to 9 blades. Additionally, you have the option to choose different classified cutters based on your budget.

|

BIT DESIGN

| |

| size | 17-1/2inch |

| IADC Code | S333 |

| Body type | Steel Body |

| Blade Count | 7 |

| Primary Cutter Size | Ф16 mm |

| Gage Cutter | Ф16 mm |

| Nozzles | #10*5 |

| Gauge Length | 2.5" in |

| API Connection | 7-5/8REG |

| Weight | 228KG |

|

OPERATIONAL PARAMETERS

| |

| Weight on Bit (KN): | 66-198 |

| RPM Range(Rotary): | 100- DHM |

| Flow Rate(lps): | 28- 39 LPM |

| Make-Up Torque(KN): | 9-12.2KN.M |

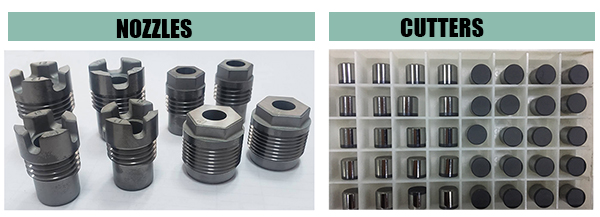

Drill Bit PDC Cutters

PDC Cutters, made of Polycrystalline Diamond Composite (PDC), serve as the primary contact point for drill bits. These cutters are primarily responsible for efficiently removing rock during drilling operations. Operating in a challenging environment, PDC cutters are subjected to frequent heating and cooling within the well.

To ensure optimal performance, PDC cutters with superior thermal stability and minimal thermal deterioration are preferred. Such cutters exhibit higher Rate of Penetration (ROP) and enhanced wear resistance. Therefore, it is essential to optimize the selection of the cutters.

Drill Bit Nozzles

Drill bit nozzles play a crucial role in maintaining the temperature of the Polycrystalline Diamond Composite (PDC) cutters and clearing the cutting zone. The positioning and angle of these nozzles significantly impact the drill bit's effectiveness. Additionally, fluid channels, coupled with the nozzle's location, improve the removal of cuttings.

Steel Body PDC Bits

In contrast to matrix bodies, steel bodies provide a high level of impact resistance due to the strength and ductility of steel. Although softer and lacking protective features, steel bit bodies can withstand severe impact loads. Moreover, worn or damaged cutters can be easily replaced, allowing for multiple rebuilds. This feature is particularly beneficial for operators working in low-cost drilling environments.

Compared to roller cones, polycrystalline diamond compact (PDC) drill bits have a single, non-moving body. This design allows PDC bits to operate at faster rotation rates, effectively shredding rock formations.

Why Choose PDC Drill Bit

PDC drill bits have been successfully utilized in the oil field and have gained popularity in the Waterwell and HDD industry.

The primary advantage of using PDC bits is increased production. When properly used, a PDC bit can significantly improve the penetration rate, resulting in faster project completion, fuel savings, and reduced labor costs per hole.

Another benefit of PDC bits is the reduced stress they place on drill rigs. They require less weight on the bit compared to roller cones, and typically require less push/pull force. This translates to less torque, reduced stress, and vibration on drilling rods.

PDC products have no moving parts and produce clean holes with consistent cutting sizes.

|

|

Drilling Well Bit 22 " Diamond PDC Drill Bit of Oilfield Drilling Tool Images |